What Is The Chemical Makeup Of A Tesla Battrie

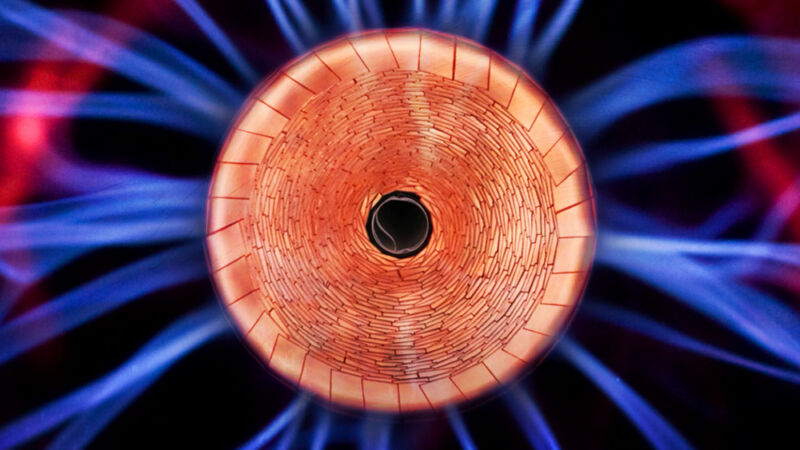

Enlarge / Gaze upon Tesla'due south new battery cell, but don't despair.

Aurich Lawson / Tesla / Getty Images

Tesla's "bombardment day" Tuesday revealed a surprising amount of information about projects the company has kept nether wraps. The presentation described changes and improvements to just about every aspect of its battery packs, with big-flick implications for the merits that a $25,000 Tesla vehicle would be possible in about iii years. (See the previous coverage from Ars' Timothy Lee for more on that.) Only it wouldn't be a Tesla announcement without vague timelines, and it was a little unclear which improvements are ready to go now—and which ones they're just expecting to succeed in the next couple of years.

Without specific numbers or physical details, assessing the announcements takes a little guesswork. Merely we can compare all this to other industry trends and to published enquiry to get some idea.

Battery in a can

Permit'southward commencement with two things Tesla claimed already be at its airplane pilot production found: its new prison cell pattern and some improvements in manufacturing. Tesla got off the ground using existing and unremarkably bachelor cylindrical 18650 lithium-ion cells, while nearly EVs have been congenital with flat pouch or prismatic cells (more like the thin batteries in phones and laptops). In a cylindrical cell, long sheet-like anodes, separators, and cathodes are sandwiched, rolled upwardly, and packed into a cylinder-shaped tin can. The cathode and anode sheets each have one skinny "tab" that connects to the positive and negative terminals of the battery can.

One of the best ways to make a battery more energy dense is to get rid of as much packaging as possible. Make the separator super thin and minimize the space-eating outer container and battery pack components, and you've got more electricity stored per kilogram. Obviously at that place are limits to how much you can shave off, so another way of doing this is increasing the ratio of battery volume to packaging area. That is, make a bigger can.

Tesla did this when it introduced the 2170 cell with the Model 3 and Powerwall. This cylinder was 21 millimeters by 70 millimeters rather than the xviii by 65 dimensions of the 18650 jail cell. Merely going bigger presented Tesla with challenges considering a bigger can holds longer rolls, and longer rolls hateful the anode and cathode stretch out further from the tab connecting them to the battery terminals. The longer path for electrons causes problems for rubber rapid charging and creates more rut that has a harder fourth dimension escaping.

Tesla's solution to this, leading to a much larger 4680 cell, is a new "tabless" design with contacts running the length of the anode and cathode sheets—forming a rose-similar gathering at the ends when everything is rolled upwardly—keeping the electrical path length to the final curt throughout the sail. "Sometimes, what's elegant and simple is however hard," Tesla's Drew Baglino said. "And it took us a lot of trials, but we're happy where we concluded up."

"It may sort of sound a bit silly to some people," Musk added, "[but] for people that really know cells, this is a massive breakthrough."

Overstate / Elon Musk and Drew Baglino present in front end of a slide showing Tesla's new "tabless" cell design.

Tesla

Information technology's genuinely hard to know precisely how this stacks up with cells used in other EVs, given how secretive manufacturers are, but it could be that this tabless design validates Tesla's choice to stick with the cylindrical cell shape.

The other one-half of making a new kind of cell is designing the machines that practice the making. As detailed in our companion story, Tesla has found means to substantially increment the throughput of portions of the bombardment line. The tabless design really helps with this, every bit the electrode canvas can just keep flying through the rollers. And together with other changes we'll get into in a moment, they're talking well-nigh increasing production while using less factory floorspace and less energy. That will help them reach cost reduction goals and ramping output goals.

Pack it up, pack it in

An EV doesn't run on a battery prison cell, of course, simply rather a bombardment pack full of cells. In that location'due south a lot going on in these bombardment packs, including charge management, cooling, and safety measures in instance of fire. That makes the technology of the pack very much relevant to the overall energy density of the vehicle'due south storage, and therefore its range.

Tesla described a new pack pattern that reduces some of the structural supports, which ways more than cells in less book. And as this involves a redesigned pack that doubles as structure for the vehicle, it probably carries some toll benefits at the vehicle level, as well.

This pack design presumably exists, simply at that place was no give-and-take on which vehicles it volition go into. Might production switch over on an existing vehicle, or is this design simply part of the Cybertruck, Tesla Semi, or unnamed $25,000 vehicle? Musk didn't say.

But he did accept a lot to say about the chemistry inside the new battery cells. And this is where the timelines get hazier. New chemistries for both the anode and cathode were discussed—both would break new ground.

The anode in modern lithium-ion batteries is graphite. The construction of graphite allows it to host the lithium atoms that move toward the anode during charging, but that'southward all it does. This ways that a substantial portion of the prison cell's volume and weight doesn't directly contribute to free energy storage beyond simply keeping the thing working. If you lot could ditch some book and weight there, the energy density of the jail cell would increase.

Tesla and some other manufacturers currently add a bit of silicon within that graphite, every bit this enables the same book of anode to hold more than lithium. A significantly better (and cheaper) pick would be the use of pure silicon. But while graphite allows lithium in and out without irresolute shape, silicon has a nasty habit of expanding every bit it loads up with lithium. That creates structural failures within the silicon, degrading operation over time, and potentially dangerous failures of the cell container.

At that place'southward a lot of research on alternative anodes for lithium-ion batteries, but none has quite reached the market. Tesla claims to accept designed an anode with tiny silicon particles in a conducting, elastic polymer. That allows for a long-lived and safe silicon anode cell, it says—which would be a big deal.

This cell comes with a claimed cost decrease from about $10 per kilowatt-hour for silicon-in-graphite to more than like $1 per kilowatt-hour for pure silicon. Every bit for vehicle range, the company claims a 20-percent improvement. Simply no other properties (like longevity compared to its current anode) were described, so it's unclear whether Tesla is fix to put this in a battery and sell information technology today. (Though for what it's worth, information technology doesn't sound as well dissimilar from an anode material Sila Nano—a company with some Tesla alumni—says it'll start providing for electronic device batteries this year.)

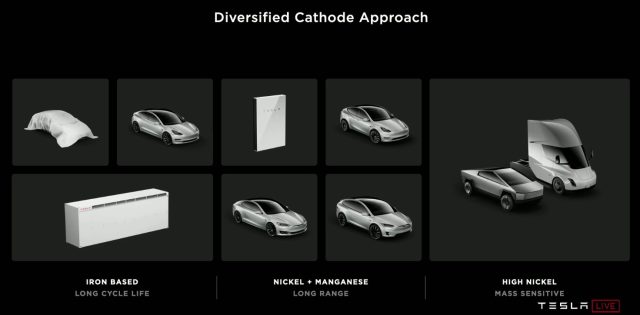

Tesla is also moving to (slightly) different chemistries on the cathode side. And yes, that's plural chemistries, which is at least as noteworthy as the nitty-gritty chemical details. Tesla now wants to provide 3 different types of lithium-ion batteries, ranging from more economic to I'thousand-giving-her-all-she'due south-got-captain.

Enlarge / Here'due south how Tesla presented its plan to use three different cathode chemistries for different applications.

Tesla

Tesla currently uses an NCA chemistry (that'southward lithium-nickel-cobalt-aluminum), while lithium-nickel-manganese-cobalt (NMC) chemistries are common beyond the rest of the EV industry. Cobalt is the most expensive of these elements, and nigh of it is sourced from mines in the Congo-kinshasa, where unsafe working weather condition and child labor are serious bug. Equally a upshot, the industry has been trying to reduce cobalt usage.

Source: https://arstechnica.com/cars/2020/09/heres-what-tesla-will-put-in-its-new-batteries/

Posted by: abbotthappold.blogspot.com

0 Response to "What Is The Chemical Makeup Of A Tesla Battrie"

Post a Comment